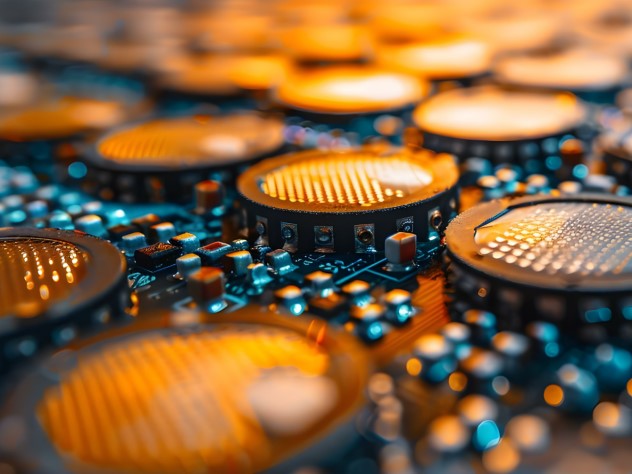

Semiconductor fabrication plants rely on the constant supply of highly sensitive, often oversized manufacturing equipment and fabrication tools to keep their production lines running smoothly and efficiently. A late or damaged shipment of capital tools can severely disrupt a fab’s production schedule.

![]()

Strict shipment handling procedures must be in place to avoid contamination and exposure to shock, tilt, vibration, or extreme temperature variation. Customers must be assured that their shipments are kept in pristine condition at every stage of the journey and will arrive on time, every time.

The best way to avoid delays and revenue loss is to use a logistics service specifically designed for the semicon industry. With an extensive network at key locations, experienced personnel, and capacity to meet the strict requirements of semicon fabs, Kuehne+Nagel can offer these specific solutions.

You can benefit from an approach founded on quality. Certified services designed specifically for the semiconductor industry ensure your supply chain always remains stable. From precise transportation to risk mitigation, professionally trained staff to preapproved suppliers—the emphasis is on providing reliable, safe, and cost-effective logistics solutions.

By partnering with us, you get a logistics provider you can trust. Our experts have a deep understanding of the industry and are on hand to tailor a solution that fits your business’ exact needs.

End-to-end support for your supply chain

The transportation of highly sensitive semiconductor manufacturing equipment is an intricate and involved process. As an experienced logistics provider, we understand that capital equipment such as major tools, pre-facility kits, conversion kits, upgrade kits, and AMHS must be handled with utmost care. That’s why we provide complete end-to-end support for transporting fabrication tools.

A network of highly trained specialists will project manage each stage of your shipment, from call-ahead preparation to pick-up, execution, and the final delivery at an identified destination. Load planning and route delivery are also taken care of, ensuring safe handling and documentation for all special requirements. All shipments should be packed in shock-absorbent, climate-controlled crates in accordance with industry best practices. Shipments are supervised and inspected at each handover point.

Combining the right people, processes, and tools allows for the efficient, safe, and timely transportation of semiconductor manufacturing equipment. You can access exclusive air freight capacity—we provide strategic weekly charter flights on our new Boeing 747-8F "Inspire", which connects key semiconductor hubs.

The infographic below provides a detailed breakdown of how to ship capital equipment internationally smoothly, quickly, and safely.

![]()

Ready to shore up your semicon supply chain with solutions built on quality and proven expertise? Contact us today and discover consistent semicon logistics you can rely on.

Take the details with you. Download our semiconductor manufacturing equipment case study.

Quality forms the cornerstone of our solutions. Customers rely on us for on-time and damage-free capital equipment logistics services so they can confidently expand their chip production operations.

Barry O'Dowd, Head of Global Business Development Semicon